Friday, September 23, 2011

Mikado on the mainline

Here she is minus a proper train, but that will be the next order of business. I made some mistakes as a first time runner, but hopefully all will smooth out over time.

Thursday, September 15, 2011

It's ALIVE!!!!!!

Well, to borrow the cliche from Mary Shelly's Frankenstien "its alive".

I'll be posting some picutres of the rest of the building process, but here is a link to see it running on stationary rollers. I'll be taking it to Norm Saley's track next week to give it a proper shake down run. Albeit a short one though as I am still awaiting a piece that will allow me to use the axle pump I have added to the kit. The axle pump will allow water to be pumped into the boiler as it runs which will extend the run as long as I keep the tender filled with water. Aster hobbies has been good at working with me in providing the parts I need.

I needed the bottom sight glass soldered or replaced, but that part is on back order currently so Norm was kind to solder the one I have up the proper way so now it can build steam pressure. Well, I'll be taking a good lengthy video of it's first proper run on track, but until then, enjoy these short clips and if you are a veteran of live steam, feel free to let me know what you think. I can get it running at a pretty low speed, so I think I have the timing near where it should be in forward gear. Notching it back a bit slows it down as well while using less steam.

Wednesday, August 10, 2011

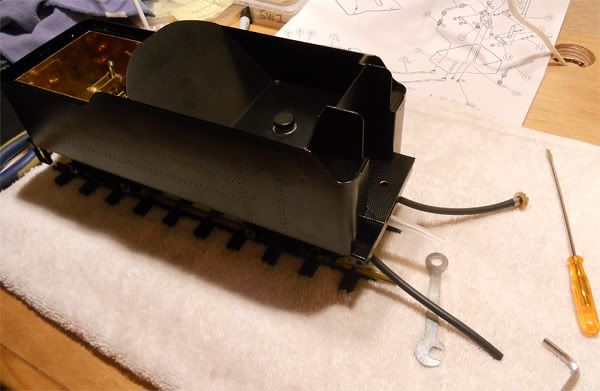

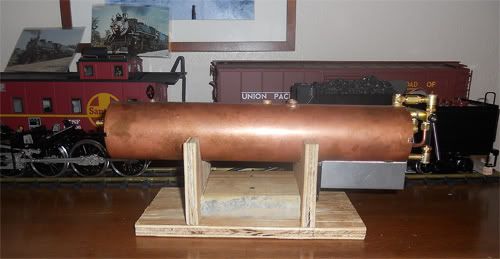

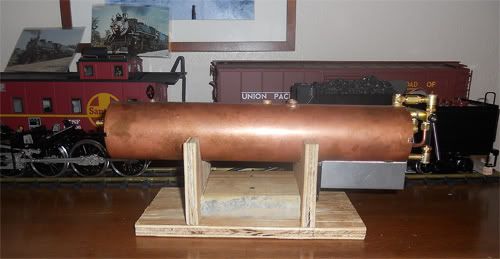

Boiler phase

So, time to do some plumbing work on the boiler to get all the fittings on. To help make it a bit easier to work on, I made a little boiler cradle out of some scrap wood.

Here I encountered a few leaks after doing a hydro test with my tender water pump hose connected to the clack valve (check valve) on the boiler back head. Using some more sealing compound I had all the ones I could fix addressed. However, there was one fitting which holds the sight glass to the bottom which I need to either have replaced or have someone solder as the solder never fully tinned the radius of the fitting. So, it leaks a lot there.

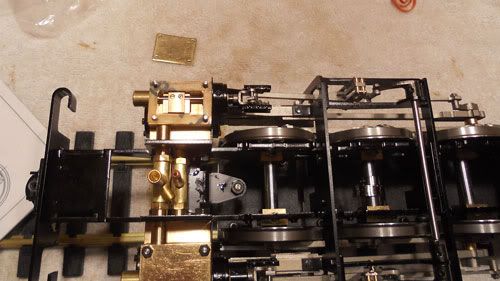

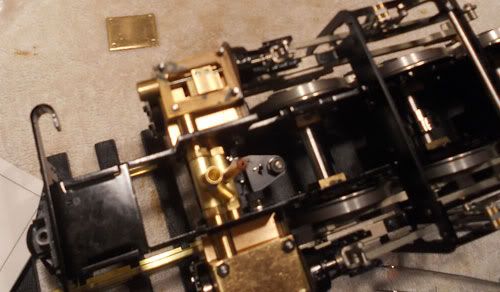

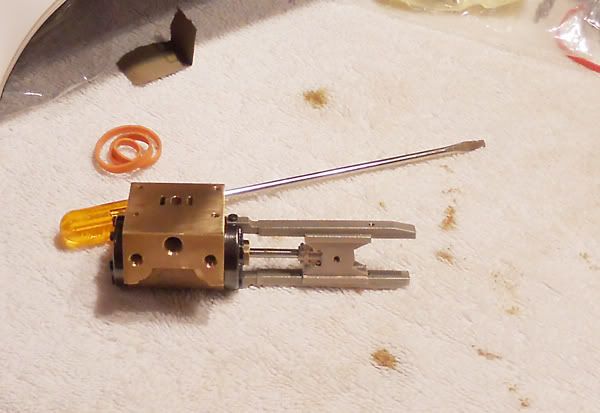

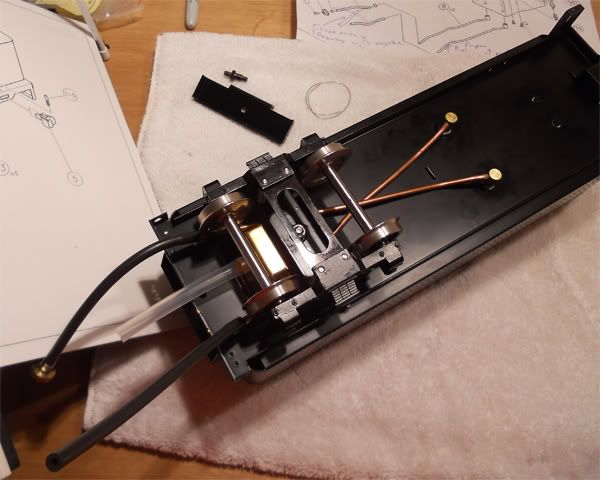

I also assembled the axle water pump and fit it on the chassis. This device will allow the boiler to be filled while under pressure with the rotation of the drivers. When the boiler is at the proper level I can open the bypass valve and return any water to the tender as the pump continues to do it's job.

It is here I encountered another issue. I am missing a part which will connect the axle water pump line to the clack valve. So, another roadblock and I have to await the part. No biggie. I don't have a deadline to get this engine running.

Here you can see the fire tubes which will superheat the steam as it passes with the steam line into the cylinders.

Now it was time to insulate the inside of the smoke box with some ceramic paper that Aster provides in the kit. This will seal up the smoke box from any outside air which might hinder the draft being created by the engine's blower and will also keep the outside of the smoke box a bit cooler to the touch, but caution will still have to be followed in handling an engine under steam.

Firebox insulated as well

Tuesday, July 26, 2011

Time.............

Well,

I got the rest of the valve gear on the chassis and spent quite a bit of time on "timing" the valve events. It involves setting the crank pin at the right angle, then having the other crank pin 90 degrees different. Then you have to adjust the slide valve via the block and set screws which bind down the block to the valve spindle. After reading over and over the directions and looking at the matching diagrams AND talking with a few people, I feel I have the valves timed for Forward motion pretty good. I put the nuts on the cylinder studs and now have to do an air test. Pushing the chassis along a length of track is great. Seeing all the working levers, arms and gear and feeling that compression from the cylinders is unlike any electric locomotive experience. I can see why those who have gone to live steam never look back at the electric train hobby.

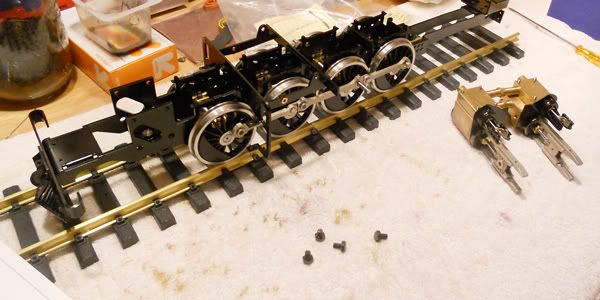

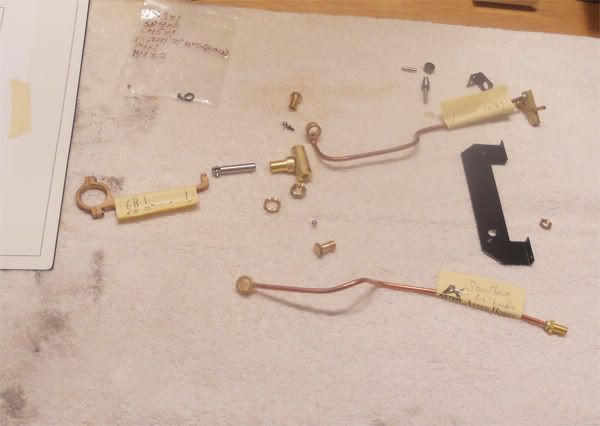

Here are the parts for the dummy brakes

Saturday, July 23, 2011

What a wonderful Wife

I just wanted to take this moment to say thanks to my wonderful Wife, Erika. She is always happy to upload my pictures I have taken during my building. I then copy those and arrange them in my posts, but she really makes things easy for me on that end. I love her and she is also the reason why I am still building. She saw the passion I had this hobby to allow me to purchase it. I would not have done so without her support. It is a sacrifice for both of us. I know that it will bring me hours of joy not only because I will get to run it, but I will get to share it with my family and especially my children, Shannon and Forest. Thanks Erika.

Mounting the cylinders to the chassis

I wanted to get the cylinders mounted to the chassis for my last step before I take a break in building due to my work schedule and not having my set of needle files arrive yet. The next section will require a bit more filing for fit than previous sections. So, I got the front and rear motion plates on which will attach to the slide bars.

Then it was time to mount the first cylinder and get the steam and blast pipes lined up.

Next, I got the second cylinder on and then fastened everything up. While the blast pipe is snug between the two cylinder steam pipes, the valve chest steam pipes do not sit quite as snug against the center steam admission pipe (threaded one). There are 0 rings inside, but I won't know till I do an air test if it will hold or leak there due to it not being quite as snug.

I also have a bit of rubbing from the front screw/washer attaching the coupling rod to the first set of drivers on the engineers side (right side looking from cab to smokestack). It seems to rub a bit when the side play allows the axle box to slide on the axle as if the train were making a left handed turn. It does not bind up the drivers but I'll have to keep an eye on that as well when I do the air test. Other than that, it went together fine. Section 3 was rather mild compared to the previous section and not as fun, but still good to have everything on the chassis and it is definitely looking more and more like a real steam locomotive.

Friday, July 22, 2011

Cylinder success

I have just completed half of section 2 which is the cylinder and valve assembly. Following the directions and using some common sense the assembly went smooth as steam oil. I chose to use Steam cylinder oil to lubricate the gaskets for the valve chest and cylinder covers. The directions call for packing compound which is a silicone caulk, but one needs to be extra careful when using it as it can squeeze into places where it should not be and clog up the steam works quite literally. I know steam oil has been used by builders before and it is something which belongs in the cylinder block anyway. It was not as messy and easier to wipe up than the silicone caulk too.

I then proceeded to put the gasket rings on the piston and assemble the cross head and slide bars which will keep the piston motion straight in the cylinder bore. Here is where some common sense is needed when deciphering the directions. To be sure, the directions are fine, however sometimes things do not translate well, but thanks to the exploded drawings, things can be figured out with some careful thought. The directions call for the builder to not tighten down the screws which hold the slide bars to the rear cylinder cover. Later I learned that the only way to access the top screw was to tighten it before installing the steam chest. I think the idea was to keep the slide bars somewhat loose to allow for correction when making sure the piston slides smoothly without any hindrances.

Next was installing the steam branch pipes to both the cylinder block and steam chest or valve chest.

Then it was time to put those cylinder studs in the cylinder block. I had previously measured them and they needed to be 12mm in height when screwed into the cylinder block to allow for enough threads to hold the nut which sandwiches everything together after the valve timing is set at a later part of the build. I did add a bit of loctite 222 to the bottom of those threads to keep them from turning when I put on the nuts later.

Now it was time to set the valve and valve block into the steam chest. I added a bit of steam oil to coat the bottom. This will come in handy later when I do an air test. I had to install some set screws into the valve block which will bind down on the valve spindle. The block grips the valve spindle which is what moves the valve back and fourth over the ports, which in turn allow steam into the cylinder to move the piston.

The valve block has two holes for those set screws. It also has a hole running the length of the block which allows the valve spindle to slide in. The hole is at the bottom of the valve block and the holes for the set screw have a countersunk depression so it is clear which side is up. The diagram clearly shows the correct position of the valve and valve block, but it is hard to mess that up as the hole for the valve spindle which runs through the valve chest clearly shows which direction the valve and block need to face. I did have to lift the block up a bit to allow the spindle to enter it and this made the block rise up and slant down sort of like a ramp. I had talked with David Leech and he said this was normal. As the valve spindle is attached to the combination lever everything will line up as it should.

Here is where the I found the directions in section 2 to be a bit out of sequence. It calls for the assembly of the cylinder back plate and valve spindle guide to be added and then the valve spindle cross-head to be installed. Here is the problem with that order. The cylinder back plate has to go on the steam chest as it is being slid down the cylinder studs for it to clear the slide bar set screw which is holding it to the rear cylinder cover. The valve spindle cross head can not be attached to the valve spindle with the valve spindle guide already attached to the valve chest. So, I had to follow the diagram more than the written instructions, but in the end everything is as it should be. The piston moves smoothly as does the valve via the valve spindle.

Now, I need to assemble the other cylinder and then it will be on to section 3 which is putting the cylinders onto the chassis.

UPDATE I have completed the second cylinder. I'll try and get some pictures up later tonight. For those interested I was given an excellent website which has tons of info on steam locomotives, but in particular with the USRA Light Mikado. You can read about it here as well as get some photos of them.

Thursday, July 21, 2011

I might shave using my cylinder block as a mirror.

Well, perhaps not.

Either way, both cylinder block faces and slide valves are lapped to my satisfaction. I ended up making them a bit shinier. I used a nice thickness of mirror I bought at IKEA. My wife will use it now that it has served my purpose. I like multipurpose items. Indeed if you pay attention to my work area, it isn't exactly something you would see at an Aster factory. I have bent wrenches as opposed to buying a socket set and so far it has worked perfectly and saved me some money. However, there is something to be said for a nice tool kit to accompany your working live steam engine.

After lapping items, I thoroughly rinsed them with water to rid them of any grit from the emery paper. Then I set them in a nice secure place to dry. The next item of business will be the assembly of the cylinder and valve chest. In between I took my slide-bars and made sure they were flat and straight and that they slid freely back and fourth in the cross-heads.

The heart of the beast

If you can imagine the human body, you can get an idea of how a steam locomotive would work. These small scale models are working models of the prototype, or "life-size" steam locomotive. This Aster USRA light Mikado is 1:32 scale or "Standard gauge". What this means is that it would take 32 of these small scale engines to represent the length of 1 prototypical sized USRA light mikado. It would take 32 stacked atop each other to represent the prototypical height and the same for the width. So all total, it would take 32,738 of these small scale live steamers aranged in 32 high, 32 wide and 32 long to equal the general outline of the prototype USRA light Mikado. (Thanks Charles)

As to our comparison here, in the human body you have the brain which sends the signals to the heart to beat which in turn sends out the blood to the parts of the body enabling it to do what the brain tells it to do. In much the same way, the engineer is the brain of the train and he would turn valves and pull levers which would send signals to the brakes, cylinders, pumps and valves to work the engine. The blood is replaced by steam in the train which enters the cylinders (heart) and moves the cylinder piston to generate motion to the coupling rods which move the driver wheels all together.

This is quite a simple comparison, but I am about to put together the heart of this beast I am building. The first thing I need to do is "lap" the face of the cylinder block and the bottom of the slide valve which will slide over the ports, which in turn allow the admission of steam into the cylinder and the outlet of exhaust into the smoke stack. When Aster machines the cylinder blocks and slide valves, little marks where the parts were milled can be seen. Putting a piece of emery paper on a flat and thick sheet of glass or a mirror allows me to smooth out these traces and gives the surface a very smooth and mirror-like finish. The Thick glass assures a flat and level surface.

I was advised to do the lapping in a "figure 8" motion so as not to apply uneven pressure going in a back and fourth motion. Some will lap with various grades of emery cloth from rough to fine and get that surface to a literal mirror-like finish. Others will do just enough. I was told by a man who works on these that no matter what finish, in the end, the slide valve will eventually create normal wear and one day for an overhaul of maintenance I might have to lap them a bit more.

I obviously will lap them enough where I won't have any steam leaks as the gasket material will create a seal between the cylinder face and valve chest. The few groves that may be left would also allow good adhesion for the cylinder steam oil. Here is a great point to say that there are differences between oil and steam oil. The basic difference is that steam oil has tallow in it which allow the oil to bond with the steam and still allow lubrication in the Cylinder assembly. For further reading on the differences you can check this article which is posted on Jim Pitt's site. http://www.southernsteamtrains.com/misc/steam-oil-hwade.htm

I have decided at this point to lay out all the pieces required for the next section on a white towel. This will serve two purposes. Firstly, it will be a great way to show the many small pieces which make up the final build and secondly it will affirm that all pieces are accounted for and milled correctly.

Monday, July 18, 2011

Taking on a new look

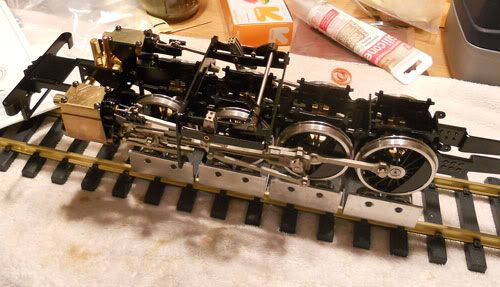

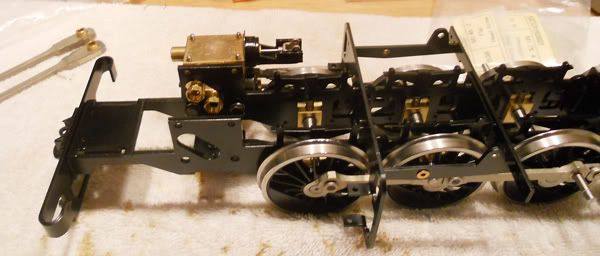

Well, having had a really nice and relaxing vacation in upstate New York, I am back in the sweatshop we call Florida. I decided it was time to finish up Section 1 which is the chassis of the Mikado. I already had the drivers and connecting rods on the frame so I needed to add the section in the back which will hold the cab and burner cups under the boiler. I also added the pilot slats, and that part alone gives this undercarriage that distinctive "steam locomotive" look. So now it was time to install the front and rear pilot pins which will hold the trucks (to be added much later in the build) to the frame.

Now, here is where I want to emphasize that building such a piece of art requires a bit of a sense of humor. What I found next simply made me laugh. These kits come from Japan. http://asterhobby.com/link2.html

The design of the model is drawn up and the pilot model is made. Then you can either purchase that engine as a kit or as a Ready To Run factory built model. While looking at multitude of small parts in the kit is daunting, it does lend to the reasoning behind some people's wish to just go with a factory built one which will steam up out of the box. However, for me, the kit will always be the way I would go if I were to give this model brothers and sisters in the future. Just the building process and sense of accomplishment I have already experienced justifies my reasons for why I went the "kit" route. I also want to say that Aster Japan has given us in the hobby of live steam a great option to get to know the ins and outs of these small scale live steam engines. The exploded drawings are very helpful and fun to follow when married with the written directions.

With that said, it should be known that in much the same way that a new novel will still have some grammatical and spelling errors that were not caught by both the human eye and computer, so too will mechanical kits, like this Mikado, have some things which will need corrected before the process of construction can be completed.

In my kit there have been a few things missing here and there, but all have been righted. I was to find that this would continue. Like I said, you can either laugh or cry about it. In this case I chose to laugh. Of those pins I mentioned earlier which will secure the front and trailing trucks to the frame's underside, three are provided. Two for the pilot truck and one for the trailing truck. The drawings clearly show that all three look different. The first pin is the longest with the second one being the shortest and the trailing truck pin being slightly longer than the second pin.

The first two pins are secured by running them from the bottom up through a hole in the frame and then fastened down with a washer and nut. The third pin simply threads into the frame which has a threaded hole. Now, when I looked at the three pins in the drawing and then the three pins I had laid out on my work surface, I began to suspect that the worker who packed my kit together at the factory may have had a bit more sake during the break than the next guy. Either that or it was simply a matter of his or her eyes seeing threads on a pin which had not been threaded.

A nut will go on threads, but try putting one on a smooth shaft. Doesn't seem to work as well does it? Well, my part 1-11 which is the second and smallest of all three pins did not have threads. I made sure I looked at it from all angles and re-read the directions a few times while looking at the corresponding diagram to be certain I in fact had a problem on my hands.

So, I had two options. I could contact Aster and request a replacement part, which I knew would put my building on hold for a few more weeks at best, or I could call up Norm Saley and see if there was anything he could do.

I had the privilege to get to meet Norm Saley back in January of this new year. He had me over to his house which is about 20 minutes away. There he fired up his Accucraft mogul which I got to see, smell and hear. If I was not hooked on the hobby of live steam before, I certainly was now. Norm Saley not only runs live steam, but he is a guru in the field of live steam repair. He invited me to bring it by and he would look at it.

Well, on Monday the 18th I did just that. He had that pin threaded in less time than it would have taken to steam up the Mikado. Easy as that and I got to watch him work. I know there are those in the hobby who have also shared this privilege at places like Diamond Head, but unlike some of those people in the hobby, I did not have to wait till next January or mail the part to him and wait for it to be mailed back. So, upon returning home, I installed the pin and Section 1 is officially completed. My next task will be lapping and building the Cylinder and valve assembly.

My Mikado chassis is really starting to take on the proper look of a steam train. At the end of the day, it felt much better to laugh about all this rather than to panic and place blame on some poor soul in Japan who might have been having an even worse day. Now, what challenge awaits me in the coming sections of this build I wonder?

Friday, June 24, 2011

On my mind

Ever have that "one" thing on your mind and until you sorted it out, you could not think of too much else? Well, not to that extreme, but one thing about building the cylinders had been on my mind. Since that is the next step in my process of constructing the Aster Mikado, I had to have a trial run. On some of the Aster Mike kits, the cylinder studs were a bit short and as you sandwich the cylinder, valve assembly together the threads on top came up short when attaching the nut atop to fasten everything together.

I don't know for certain whether or not I have short studs, but one threaded side of the stud is longer than the other. According to the assembly diagrams, the longer threaded side goes into the cylinder body with the shorter threaded side, separated by a smooth shaft, sticks out atop the valve plate and the nuts go on here. Well, if I have the longer side in the cylinder and I assemble everything together, there is not enough threads to protrude above the plate to give the nut threads to attach to. If I reverse the studs, then there is too much threads atop and it would interfere with the cylinder shrouds later on in the building process.

The two options here are to get the correct length of studs replaced by Aster, or thread the studs in then take them out enough to give more threads on top. I chose the latter option. I was given the advice to add some loctite to the bottom threads so that when I attached the nut on top it would not pull the studs out when tightening the nuts. I chose to go another route. After seeing if the method would work, I chose to add loctite to the top threads and then put the nut on with the stud filling up all the threads in the nut so the stud body was flush with the top of the nut. I will let the loctite dry and what I have effectively done is create a bolt to screw into the cylinder sandwiching everything together.

The reason I did this was on account of every time I would try to add the nut, I would end up forcing one or more of the studs further into the threads in the cylinder body. Either way would be fine I guess, but I chose to do this method. After vacation when I lap the cylinder I can just put everything together and screw in the studs/bolt.

Update: Since doing this, I have taken those nuts off and cleaned up the threads. I'll use loctite 242 on the bottom threads which go into the cylinder block instead.

I measured the height the studs need to be (which is 12mm to give the nuts on top enough threads to be flush with the nuts after snugging them down). Thanks David.

Saturday, June 11, 2011

Cooler water

In the spare time I have had, I painted the top of the tender's water tank. I used Scalecoat I "freight car red" which is a Pennsylvania railroad color that they used on freight cars as well as on the tops of tenders and cabs of the PRR locomotives (I'll be making this a PRR locomotive). I am told this is because it was a lighter color than the dark green locomotive enamel and allowed the water in the tender to stay cooler. Cooler water is better for the injectors which would take the water from the tender, mix it with steam and feed it to the boiler. I think it looks good too. I got the scalecoat paint in a spray can form from Weaver models. I partially followed their application instructions which called for baking the painted surface in an oven for several hours on a low heat of 175 degrees. I did 170 and only let it bake for 1 hour and 30 minutes as it was a very light coat on top of the factory paint. The scalecoat I colors are for brass and other types of metal. Scalecoat II is for plastics. So, if you are purchasing this paint, be sure to get the proper paint for what you will be using it on. I left the screws which attach the top to the tender black because I think it looks OK that way. I may change it later which should be quite easy.

I also have modified my coal load for the tender by crushing some smaller pieces and adding to the top for a more scale look.

after

before

Wednesday, June 1, 2011

smooth coasting

Well,

I assembled the chassis, well at least the drivers, coupling rods and horn stays.

After working through some kinks (again, no pun intended), the chassis rolled very smoothly. I was stubborn and did not use the method of using grease on the end of the screw-driver to hold the screw in place, so putting on those horn stays was really interesting and probably took longer than it should have, but I had fun. I used the mini-screwdriver that came with the kit and didn't have to make the modifications to the larger one like Marc Horovitz had to. It fit quite well in between the driver spokes.

I then secured both coupling rods. Funny thing is that when I had the coupling rods on one way, it would bind up, so I put the right one on the left side and the left on the right, and smooth rolling. I used machine oil from 3-in-1 (blue can) and looks and rolls real nice.

Now, I do promise that I am stopping now for the summer. I had to get this whole business of the coupling rods out of my system before I left for New York. I would like to take this opportunity to share a revelation I have had during this process. Here is a video clip of the chassis rolling along a length of track.

http://www.youtube.com/watch?v=pBSkqvBHf9g

http://www.youtube.com/watch?v=pBSkqvBHf9g

I appreciate when people who have "been there, done that" offer their advice. I really do. However, with that said, I feel that a few tips given to me had me worried needlessly. One was in the coupling rod's bushing holes. The fact that someone emailed me saying they had some issues gave me concern that I might get a similar experience. Well, the minute I opened up box 1 I saw the coupling rods and also noticed the bushings were drilled "off-center". OH NO! is what I thought. Well, as I found out both through experience and talking with a friend, those rods were the right fit. So, it goes to show that sometimes advice offered as a help, can sometimes lead to needless concern. I guess I have learned that I need to cross the bridge when I get to it, and not worry about it beforehand.

Either way, Hans and Aster were ready and willing to help, so I thank them. I also found that the cylinder studs I have are 19mm long which are longer than the ones supplied with some of the other kits which had "shorter" studs. Hans provided a clear picture for me showing the shorter of the two. I have the longer of the two. This again was concern born of "tips". I don't want to give the impression I am not thankful for people who offer their experiences, I am truly grateful.

Tuesday, May 31, 2011

Meeting good folks

In this hobby I have already met a lot of nice folks. People who are willing to help out a guy like me who is relatively new to live steam. I have learned a great deal over the past year by frequenting MLS.com, talking with people both via email and over the phone and seeing first hand live steam. Even smelling a coal fired live steamer thanks to Andrew.

My kit did not have a tender hand pump handle, which is used to reach down to the hand pump through the water hatch and work the pump. I mentioned this to a guy I met and talked with a few times, as he himself has built two Mikados, and he whipped me up a very nice looking brass handle on his lathe and sent it to me. I got it today. I hope I can repay the favor one day. Thanks Charles.

Loose the Binding

That was my next project. I needed to be sure I had the correctly milled coupling rods as I was told by Jeff Runge that I needed to be sure there was no binding and he had to work through a similar issue with one he assembled. So, even though my intention was not to commence the chassis assembly, I wanted to check for my peace of mind.

I put the Driver axles in the side frames and had to use a bit of oil to have them slide in a bit better. It is here where one must be careful to follow directions and diagrams to ensure the proper placement of the driving axles in their respective places in the side frame. Now was time to place the coupling rods on the drivers. Since this was only a "dry" run, I did not put the axle springs in or secure the rods with the hardware. However, I did make sure everything was where it would be had I done so.

Then I rolled it forward and it did move until a certain part where it would bind up. After consulting with people like David Leech, Jeff Runge and Hans, I was able to find the source of the binding. It was, to my relief, not the rods, but rather some tight fitting on the front most Driving axle. After some oil and some rolling back and fourth, coupled (no pun intended.....well perhaps just a little) with switching coupling rods to opposite sides, the chassis rolled very smoothly at just a touch of my finger. In both directions too. So, when I do assemble it later, I will file a bit of paint off of the frame where the axle will fit into. I carefully labeled the parts so when I put them back in the box and took them out later I would know the orientation that worked best.

Those cylinder studs won't be too much of an issue. I can always get some longer ones from Aster, or I could back out the threads a bit to give me more on top the valve covers which will allow for more threads to secure the retaining nut to.

Monday, May 30, 2011

Who needs a load of coal?

Well, I did and with some Aster kits, you need to make your own. I believe the Aster K4 had a dummy coal load provided, but making your own can be so much more gratifying. I have made them for coal hoppers on my 0 gauge set before, so I had some small sized pieces of coal. While the pieces will be a bit large for this model, but you can always break them down smaller, if it bothered you, by using a hammer. I think it still looks fine the size they are and besides, breaking it down can be messy and you have to have something to collect all those small pieces.

I had to decide which material to use for the bed which will be placed atop the fuel tank covering the needle valve and fuel filler cap. Be careful here when fitting things as there is a small breather tube near the needle valve which is uncovered. I placed a small piece of scotch tape over it during my fitting phase as I chose to use Styrofoam for both it's light weight and mold-ability. Remember to remove that tape after your fitting process if through.

I bought a small sheet of Styrofoam up at my local craft store. About 3/4 inch thick.

You may have something lying around from a shipping container, but I wanted something flat and also thin. I made a paper pattern which followed the contours and slop of the tender's coal bay. Then I traced the layout on the styrofoam board. You can either use a cutting device which is a heated wire for cutting (less mess, but more fumes) or you can use a hobby knife/box cutter. I had the latter so I carefully cut out the pattern. I then used a lighter to burn and also melt the small pieces of foam so it would not continue to shed each time it was moved. I also used the lighter to burn some dimples in the top of the load so it would not be perfectly flat when I applied my first layer of coal to it.

After checking the fit, I cut a small loop of thin and flexible wire to feed into the foam for a way to lift the coal load out of the tender when needed. Then I painted the whole piece with a matte black spray. After drying, I covered the bottom of the foam in clear packing tape. If the load were to ever break, it would not be in two pieces and it will stop any small pieces that might fall of the bottom from entering the breather tube.

Now it was time to glue on the first layer of coal. I was reminded by David Leech to not use a water soluble glue as being outside under rain could prove disastrous for your coal load. I chose a multipurpose glue for all weather conditions, or so it said on the bottle. I chose something which would dry clear as well, like Elmers does. It is called WELDBOND and is non-toxic.

After applying a layer of glue I sprinkled the coal down and allowed it to dry. When dry, you can turn the load upside down and the pieces that did not stick can be gathered up and used for the second layer which will add more realism to the coal. Now it is a matter of personal preference on how to continue to build the load of coal.

I had to decide which material to use for the bed which will be placed atop the fuel tank covering the needle valve and fuel filler cap. Be careful here when fitting things as there is a small breather tube near the needle valve which is uncovered. I placed a small piece of scotch tape over it during my fitting phase as I chose to use Styrofoam for both it's light weight and mold-ability. Remember to remove that tape after your fitting process if through.

I bought a small sheet of Styrofoam up at my local craft store. About 3/4 inch thick.

You may have something lying around from a shipping container, but I wanted something flat and also thin. I made a paper pattern which followed the contours and slop of the tender's coal bay. Then I traced the layout on the styrofoam board. You can either use a cutting device which is a heated wire for cutting (less mess, but more fumes) or you can use a hobby knife/box cutter. I had the latter so I carefully cut out the pattern. I then used a lighter to burn and also melt the small pieces of foam so it would not continue to shed each time it was moved. I also used the lighter to burn some dimples in the top of the load so it would not be perfectly flat when I applied my first layer of coal to it.

After checking the fit, I cut a small loop of thin and flexible wire to feed into the foam for a way to lift the coal load out of the tender when needed. Then I painted the whole piece with a matte black spray. After drying, I covered the bottom of the foam in clear packing tape. If the load were to ever break, it would not be in two pieces and it will stop any small pieces that might fall of the bottom from entering the breather tube.

Now it was time to glue on the first layer of coal. I was reminded by David Leech to not use a water soluble glue as being outside under rain could prove disastrous for your coal load. I chose a multipurpose glue for all weather conditions, or so it said on the bottle. I chose something which would dry clear as well, like Elmers does. It is called WELDBOND and is non-toxic.

After applying a layer of glue I sprinkled the coal down and allowed it to dry. When dry, you can turn the load upside down and the pieces that did not stick can be gathered up and used for the second layer which will add more realism to the coal. Now it is a matter of personal preference on how to continue to build the load of coal.

For now I am satisfied with my coal load and can always tweek it a bit if I so choose.

Sunday, May 29, 2011

Thanks

I would like to add, that the way I was able to obtain this Kit was through a selfless act of kindness on the part of the individual who sold it to me. The seller was not necessarily looking to sell, but rather gave up their own plans for the kit. Thanks. I wish all those who are in live steam could share the joy of building a kit and seeing it come to life. I have built many model kits as well as architectural models and they were fun, but in the end, they could only be set aside for decoration or dust collecting duties. This kit is something which I will be able to take pride and joy from and share it with my family. I work with children and I will be able to share this with them as well and introduce them to the hobby of live steam. If you are pondering what to get for your first engine, or perhaps your "next" engine, why not try a kit if you have never built one before. I would buy any kit, no matter the manufacturer, if it were of this quality again. I can highly recommend Aster. Not because of the name, but because of the experience.

I would also like to take this opportunity to thank the people that have been of much assistance over the course of the last year which has been my journey into learning about live steam. mls.com has a page on live steam, which is where I learned a lot. People like Charles, Ryan, Semper Vaporo(charles), Jeff, David, Art, Mike, Norm, Jim, Harlan, Hans, Will, Rob,Dan,Tac,Andrew and many more I have not mentioned have helped me learn the ropes of live steam. Thanks guys. I hope to meet those I have not yet at a steam up one day.

Details

I added the detail parts to the tender which were the steps, ladder, rear coupler and front pin for coupling to the engine.

Some notes on the details. I experienced more trouble trying to get that collar on the pin after the spring and washer were on, then any other part of the kit this far. Not to be deterred, I took my time and used an allen wrench to push the collar onto the pin's slot. (My fingers were too sore from tying to push it on). It was interesting using one hand/screwdriver to hold down the washer and spring and the other to push on the collar. It helped that the pin was held in the hole by the fuel tube below it, but eventually I had to turn the tender upside down. Seemed to be easier that way. Having a white towel is great for both discouraging the bouncing/rolling of dropped hardware and creating a soft work surface to keep the kit from unnecessary abrasions.

I had to file a bit of the side (hidden behind the tender bottom edge) of one step to align with the threaded holes. Other than that, no big problems. Now it is time to make the dummy coal load.

Holds fuel and water with no leaks, the pump works smoothly (no pressure to over come in boiler at this point) and the fuel needle valve closes the flow of fuel properly.

Some notes on the details. I experienced more trouble trying to get that collar on the pin after the spring and washer were on, then any other part of the kit this far. Not to be deterred, I took my time and used an allen wrench to push the collar onto the pin's slot. (My fingers were too sore from tying to push it on). It was interesting using one hand/screwdriver to hold down the washer and spring and the other to push on the collar. It helped that the pin was held in the hole by the fuel tube below it, but eventually I had to turn the tender upside down. Seemed to be easier that way. Having a white towel is great for both discouraging the bouncing/rolling of dropped hardware and creating a soft work surface to keep the kit from unnecessary abrasions.

I had to file a bit of the side (hidden behind the tender bottom edge) of one step to align with the threaded holes. Other than that, no big problems. Now it is time to make the dummy coal load.

Holds fuel and water with no leaks, the pump works smoothly (no pressure to over come in boiler at this point) and the fuel needle valve closes the flow of fuel properly.

I am trying to track done some "longer" cylinder studs as the ones supplied in my kit are too short. Aster should have some stock left of these parts. Good thing I won't be building till late summer anyway.

Saturday, May 28, 2011

Plumbing the Mikado's tender pump

So, after seeing that the fuel tank was installed without issues, I decided to finish the tender by building and installing the tender pump. Here is another example that shows all one really needs other than the kit, instructions and tools is common sense. Where the instructions dictated one part number, my exploded diagram showed a different part number. Well, looking at the part and visualizing how it was going to work and how the drawings showed it assembled, I got er done.

It was a joy seeing the final pump assembly after looking at all those parts and having the question in the back of my mind, "are all the parts here?", certainly gave me a bit of concern. My kit had the pump kits added after market and some were in bags written on by the dealer. I am still looking for the pump handle that the drawings show, but I have a replacement pump handle on the way, so no worries there.

Now it was on to installing the copper pipes that will feed the boiler and allow the return water back into the tender when the bypass valve is open. The purpose of the tender pump is to inject water into the boiler both when starting up and under pressure. There are steel balls that act as clack valves which only allow water to be sent in one direction. This is at least the theory of how they work. Sometimes dirt and such can get in there and cause the functionality to change a bit. In writing this blog, it is the author's assumption that those reading it have a basic understanding of how the parts that make up a small scale live steam engine work. If you are interested in learning a lot more there is a good book I can recommend. A PASSION FOR STEAM by Marc Horovitz.

After seeing how I wanted to arrange the pipes, I mounted the pipes into their unions after applying some packing compound to give a good water tight seal between the tender and tender water receptacle which is made up of sheets of brass soldered together. There are holes where the water pipes from the water pump must connect with the copper lines underneath the tender, so you don't want all your water wasted because you didn't seal up the holes good.

I then mounted the tender hand pump and connected the lines inside the tender to the outside lines. I also had to bend a few small wrenches to better fit the unions in the tight corners. No, those aren't forged steel wrenches, they are thin steel ones. It sure beat going out to hunt down something which would work.

After assembling and installing the water lines and tender pump I put on the rubber hoses and attached the threaded fastener which will connect one of the lines to the boiler supply line that will be on the engine.

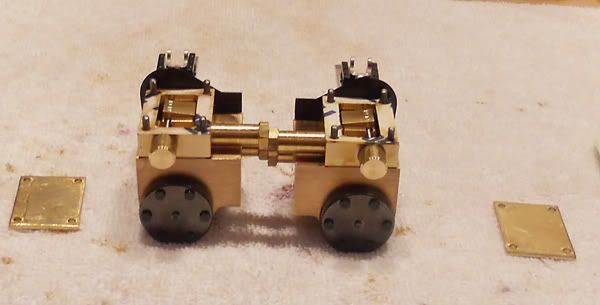

Next it was time to put those trucks I had assembled yesterday onto the tender. Everything went together a bit easier than I had expected, but I did have some moments where I had to stop and think how it would be best to do something. I am very pleased so far. Next I will add some detail parts to the tender and make a "dummy" coal load for aesthetic purposes when it graces my shelf between steam ups. There will be no storage box for this loco.

Tonight after the packing compound has dried, I'll do a water test to make sure I won't be wasting any water needlessly. I'll also give the pump a few strokes to test it as well. I will be taking a break for the summer vacation so I will not be working on the engine until I return later in July. I hope all who have read this have been both entertained and enlightened. I am really glad to have the chance to build this engine to both better understand it's workings and to have something which will last me to share the fun with my son and daughter.

Packing dried, so I tested it. No big leaks, but there was a droplet of water forming under one of the mounting screws of the pump, so I added a touch more caulk around that screw.

Subscribe to:

Posts (Atom)